Rotary mixer is a kind of mixer with high mixing quality quick mixing speed and complete discharging.

Consult now

Scan the QR code on the left

Follow and add friends for consultation

Rotary mixer is a kind of mixer with high mixing quality quick mixing speed and complete discharging.The mixer has two forms: one is experimental (MX series) which is mainly used for laboratory or small batch production (working volume from 7L ~ 450L);The other type is production (SLH series) it is mainly used for mass production (working volume from 0.3m3 to 17m3).The mixer is mainly used for solid-solid (powder and powder) solid-liquid (powder and liquid) mixing.Application industries are chemical food pharmaceutical coal metallurgy ceramics pigments dyes pesticides explosives and so on.Its applicable materials include food oil to carbon black coating spices to talc coating refractory materials combustible and explosive materials grinding materials carbon fertilizer condiments wood powder and clay chemical products etc.

| 型号 | 筒体内径(mm) | 参考动力 | 全容积 | 工作容积 | |||

| mm | KW | HP | m3 | ft3 | m3 | ft3 | |

| SLH-0.3 | 1150 | 1.1 | 1.5 | 0.6 | 20 | 0.3 | 10 |

| SLH-0.45 | 1400 | 1.5 | 2 | 0.9 | 30 | 0.45 | 15 |

| SLH-0.6 | 1650 | 4 | 5 | 1.2 | 42 | 0.6 | 20 |

| SLH-1 | 1850 | 7.5 | 10 | 2 | 76 | 1 | 40 |

| SLH-1.5 | 2000 | 11 | 15 | 3 | 105 | 1.5 | 53 |

| SLH-2 | 2300 | 15 | 20 | 4 | 150 | 2 | 75 |

| SLH-2.5 | 2300 | 18.5 | 25 | 5 | 180 | 2.5 | 90 |

| SLH-3 | 2500 | 18.5 | 25 | 6 | 220 | 3 | 110 |

| SLH-4 | 3000 | 22 | 30 | 8 | 280 | 4 | 140 |

| SLH-5 | 3000 | 22 | 30 | 10 | 360 | 5 | 180 |

| SLH-8.5 | 3300 | 30 | 40 | 17 | 600 | 8.5 | 300 |

| SLH-13 | 3300 | 45 | 60 | 25 | 900 | 12.5 | 450 |

| SLH-17 | 3600 | 55 | 75 | 34 | 1200 | 17 | 600 |

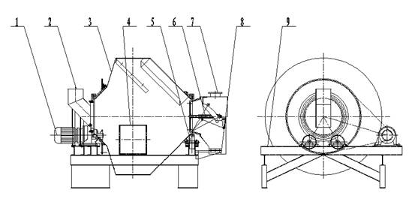

1、Drive Unit 2、Inlet 3、Trough 4、Manway 5、Roller Unit 6、Discharge Valve 7、Vent 8、Outlet 9、frame

1.The mixing process is gentle and the mixing uniformity is high.The unique internal design of lifting plate and discharge plate ensures a gentle mixing movement of materials in a very short mixing time: falling turning and overlapping during the mixing movement.

2.Mixing speed is fast. The material can be evenly mixed within three minutes;

3.Low energy consumption.The mixing barrel is supported by a heavy "trunnion rollers" and driven by a driving device.This design allows for quick easy maintenance and the lowest possible horsepower drive.

4.Discharge thoroughly.The internal lifting plate and discharge plate are installed at a certain Angle and the unique discharge mechanism can ensure the clean discharge;

5.Good tightness.Fully enclosed design to prevent dust harmful gases and substances from entering.The special sealing design can ensure the complete sealing of the static and dynamic joint.

6.Loading range.The same effective mixing can be achieved when the loading coefficient is less than 0.5;

7.Choice.Users can choose jacket or spray device according to the process requirements so as to heat and cool the material or spray an appropriate amount of liquid into the material.